BLOG

From Pod to Palate: The Bean to Bar Chocolate Process

The Artisanal Journey of Bean-to-Bar Chocolate Making

If you’re a chocolate lover, bean to bar might be a new buzz-word in your vocabulary. But what does it actually mean?

Bean to bar is a term used for chocolate that has been manufactured all the way from bean-to-bar, rather than being mass produced by a company. Let’s explore the bean to bar process and provide some benefits of going with our organic bean to bar chocolate!

Sourcing the Finest Cacao Beans

At Mr Popple’s Chocolate, we understand that the foundation of exceptional bean-to-bar chocolate lies in the quality of the cacao beans. That’s why we go to great lengths to source the finest, ethically grown cacao from our trusted partners in Peru.

We work with organic farmers who cultivate the rare and highly prized Criollo variety of cacao, known for its delicate, complex flavour profile. By fostering relationships with these farmers, we ensure that they receive fair compensation for their hard work and dedication to sustainable farming practices.

The Art of Fermentation and Drying

Once the cacao pods are harvested, the real magic begins. The beans and pulp are removed from the pods and undergo a meticulous fermentation process that lasts around 5 days. This crucial step is where the chocolate’s flavour profile begins to develop, as the fermentation reduces bitterness and brings out the beans’ natural complexity.

After fermentation, the beans are carefully sun-dried for up to 2 weeks to achieve the perfect moisture content. Drying the beans means that the moisture inside decreases from 60% to around 6%. Water is chocolate’s biggest enemy, believe it or not… any excess moisture can really throw up some problems at any and every stage of the chocolate making process. So, it’s really important to dry the beans and respect H2O!

Unleashing the Raw Power of Cacao

In most instances, the dried beans are then roasted to enhance their flavour. However, at Mr Popple’s Chocolate, we skip this step in order to preserve all the raw goodness, such as antioxidants and polyphenols that would otherwise be lost in the roasting process.

By using unroasted cacao beans, we harness the raw power of this superfood, ensuring that our chocolate is not only delicious but also packed with health-promoting compounds. Studies have shown that raw cacao is one of the most antioxidant-rich foods on the planet, offering a wealth of benefits for your heart, brain, and overall well-being.

Cracking and Winnowing: Unveiling the Cacao Nibs

The cacao beans are then cracked and winnowed, which means that they are shelled and cracked into smaller pieces called cacao nibs. These are the most desirable part of the bean. Then they’re checked for pathogens, a really important step in this process.

From Nib to Liquor: The Grinding Process

The nibs are then ground into a thick, luscious paste known as chocolate liquor. At Mr Popple’s Chocolate, our cacao nibs are put through a stone grinder for several days in order to produce the best quality, healthiest chocolate.

The Art of Conching: Developing Flavour and Texture

After the grinding process, the chocolate liquor undergoes conching. This process is where the true flavour of chocolate is born! When conching takes place, cocoa butter is distributed evenly, and the characteristic chocolatey flavour is developed. Conching also helps to create a smooth, velvety texture in the finished chocolate.

The Tempering Touch: Achieving the Perfect Texture and Shine

The final step before moulding is tempering, where the chocolate is heated and cooled at precise temperatures to stabilize the cocoa butter crystals. This is a vital step of the chocolate making process, as if this step is done incorrectly, the chocolate won’t have the best shine or snap, and blooming (unsightly white marks) can appear on the chocolate bars.

When tempering is done perfectly, it gives the chocolate a velvety smooth texture, gleaming shine, and a satisfying snap when broken.

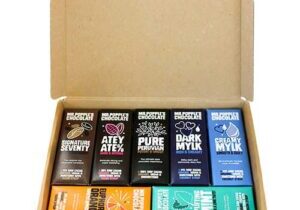

The Bean-to-Bar Advantage: Why Mr Popple’s Chocolate Stands Out

So, what sets bean-to-bar chocolate apart from its mass-produced counterparts? For starters, the superior taste and quality are undeniable. By overseeing every step of the process, from sourcing the beans to crafting the final bars, bean-to-bar chocolate makers like Mr Popple’s have complete control over the flavour profile and integrity of their products.

Moreover, the bean-to-bar process offers unparalleled transparency and traceability. You know exactly where your chocolate comes from and can trust that it’s been made with the utmost care and attention to detail. At Mr Popple’s, we’re not just passionate about crafting chocolate that tastes great; we’re also dedicated to supporting ethical and sustainable practices every step of the way.

What truly sets Mr Popple’s apart is our commitment to keeping the cacao raw throughout the entire process. We are one of a very small number of bean-to-bar chocolate makers who preserve the raw power of cacao, ensuring that our bars are packed with antioxidants, polyphenols, and other health-promoting compounds.

The bean to bar process is a lot of work, but we think it’s totally worth it! If you’re a bean to bar chocolate lover, make sure to check out our organic bean to bar chocolate range today and experience the difference for yourself.