BLOG

The Role of Cacao Winnowing in Crafting High-Quality Bean-to-Bar Chocolate

The bean-to-bar chocolate making process is a fascinating journey that transforms the humble cacao bean into a decadent, melt-in-your-mouth delight.

At Mr Popple’s Chocolate, we’ve been perfecting this art since 2007, and we know that every step along the way plays a crucial role in creating the highest quality chocolate.

From sourcing the finest cacao beans to the final tempering and moulding, each stage requires meticulous attention to detail.

This article spotlights one of the most significant, yet often overlooked, steps in the process: cacao winnowing.

Winnowing Hearts and Minds – Ethically Sourcing the Best Cacao to Crack and Winnow

Our bean to bar journey begins with the ethical sourcing of premium cacao beans from around the world.

Currently, we’re focusing on exquisite Peruvian Criollo cacao, renowned for its delicate, complex flavour profile.

Before the cacao beans even reach the winnowing stage, they must undergo a meticulous sorting process to ensure that only the highest quality beans make it into our chocolate. This crucial step involves carefully inspecting each bean, looking for any signs of damage, mould, or other imperfections that could negatively impact the flavour and quality of the finished product.

Our skilled artisans check for uniformity in size and colour, as well as any insect damage or foreign objects that may have found their way into the batch. Beans that are too small, too flat, or have a slatey or violet colour are discarded, as they can impart off-flavours or indicate improper fermentation.

By hand-sorting our cacao beans, we can guarantee that only the best of the best make it into our chocolate, resulting in a consistently exceptional product that showcases the true potential of the cacao bean.

Shelling It Like It Is: The Significance of Cacao Winnowing in Artisanal Chocolate Production

Cacao winnowing is the process of separating the precious cocoa nibs from the inedible husks. This essential step ensures that only the purest, most flavourful parts of the cacao bean make it into your chocolate bar.

Incomplete or improper winnowing can have a detrimental effect on the quality of the finished product, as any remaining husk fragments can impart bitter, astringent notes that detract from the chocolate’s natural flavour profile.

The Impact of Quality Cacao Winnowing on Chocolate Flavour and Texture

Have you ever wondered why some chocolate bars taste smoother and more flavourful than others? One of the secrets lies in the quality of the cacao winnowing process.

Proper winnowing enhances the natural flavours of cacao by removing the bitter, astringent notes that can detract from the chocolate’s inherent taste profile.

When cacao beans are cracked and winnowed, the goal is to separate the precious nibs from the inedible husks. However, if the winnowing process is incomplete or ineffective, small fragments of husk can remain in the nibs. These fragments contain tannins, which impart an unpleasant bitterness to the chocolate. By minimizing the presence of these bitter tannins, artisanal chocolate makers can showcase the true depth and complexity of their cacao.

Moreover, effective winnowing leads to a smoother, more refined chocolate texture. When the nibs are free from husk fragments, they can be ground into a fine, uniform paste, which is essential for creating a silky smooth chocolate that melts effortlessly on the tongue. This luxurious mouthfeel is a hallmark of premium, bean-to-bar chocolate, and it all starts with meticulous winnowing.

Artisanal Bean-to-Bar Chocolate Makers: Prioritizing Cacao Quality and Sustainability

In recent years, there has been a growing demand for premium, ethically-sourced cacao. Discerning chocolate lovers are seeking out bars that not only taste exceptional but also align with their values of sustainability and fair trade. Artisanal bean-to-bar chocolate makers are rising to meet this demand, prioritizing cacao quality and building strong relationships with farmers.

These dedicated craftsmen and women understand that the key to creating outstanding chocolate lies in the quality of the cacao beans. They seek out well-fermented, sun-dried cacao beans with minimal husk content, often paying premium prices to ensure they receive the finest raw materials. By working directly with cacao farmers and cooperatives, artisanal chocolate makers can build sustainable relationships that benefit both parties.

These partnerships not only guarantee a consistent supply of superior cacao but also support farmers in implementing best practices for cultivation, fermentation, and drying. By investing in the success and well-being of cacao farming communities, artisanal chocolate makers are helping to create a more equitable and sustainable future for the industry.

From Winnowing to Finished Product: The Remaining Steps in Bean-to-Bar Chocolate Making

Once the cacao beans have been winnowed, the resulting nibs are ready to be transformed into the chocolate we know and love.

The first step in this process is grinding the nibs into a fine paste, known as cocoa liquor. We do this with a stone grinder, which breaks down the nibs and releases their natural oils, creating a smooth, liquid consistency.

Next, the cocoa liquor is combined with other ingredients, and refined to further reduce the particle size and enhance the texture. This step is crucial for achieving the smooth, melt-in-your-mouth feel that is the hallmark of high-quality chocolate.

The refined chocolate then undergoes a process called conching, where it is mixed and aerated for an extended period, often several days. Conching helps to develop the chocolate’s flavour profile, removing any remaining acidic or astringent notes and creating a harmonious balance of tastes.

Finally, the chocolate is tempered, moulded, and packaged. Tempering involves carefully heating and cooling the chocolate to create a stable crystalline structure, which gives the finished product its glossy sheen and satisfying snap. The tempered chocolate is then poured into moulds, allowed to set, and packaged for distribution.

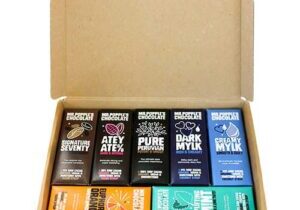

Mr Popple’s Bean to Bar Chocolate: The Winnowing Choice

At Mr Popple’s Chocolate, we have been crafting exceptional bean-to-bar chocolate since 2007. Our commitment to sourcing the finest cacao beans from around the world is at the heart of everything we do. We work with farmers and cooperatives in Peru, ensuring that our cacao is ethically sourced and sustainably grown.

We understand that the quality of our chocolate is only as good as the quality of our cacao, which is why we ensure the nibs are meticulously separated from the husks, ensuring that only the purest, most flavourful cacao makes it into our chocolate.

By prioritizing cacao quality and mastering the art of winnowing, we are able to craft chocolate that showcases the true potential of the cacao bean. Each bar is a testament to the skill, dedication, and passion that goes into every step of our bean-to-bar process, from sourcing to winnowing to final production.

Key Takeaways

The significance of cacao winnowing – the process of separating the precious cocoa nibs from the inedible husks – cannot be overstated in the bean-to-bar chocolate making process . This crucial step is the key to unlocking the full flavour potential of the cacao bean and creating chocolate with a smooth, refined texture.

Quality winnowing has a profound impact on the final product, enhancing the natural flavours of the cacao and minimizing the presence of bitter tannins from husk fragments.

We hope this article helps you appreciate the artistry and dedication that goes into making premium bean-to-bar chocolate. By supporting artisanal chocolate makers who prioritize ethical sourcing, sustainable practices, and meticulous craftsmanship, we can indulge in the rich, complex flavours of high-quality chocolate while also contributing to a more equitable and responsible industry.