BLOG

The Science of Chocolate Conching: The Secrets Behind Silky Smooth Bars

Have you ever wondered how chocolate makers transform a gritty mixture of cacao nibs and other ingredients into the smooth, melt-in-your-mouth chocolate we all know and love?

The secret lies in a process called conching, a crucial step in the bean-to-bar chocolate making journey that takes place after the ingredients have been ground together.

What is Chocolate Conching?

Conching is the process of mixing, agitating, and aerating chocolate at a controlled temperature for an extended period, typically ranging from a few hours to several days. This process is named after the shell-shaped vessels, called conches, that were originally used to perform this task.

The conching process plays a vital role in developing the final texture, flavour, and aroma of the chocolate. It helps to evaporate any remaining moisture, remove unwanted volatile compounds, and distribute the cocoa butter evenly throughout the mixture, resulting in a smoother, more homogeneous product.

The Science Behind Conching: Transforming Texture and Flavour

During the conching process, the mechanical energy input from the mixing and agitating action is crucial in achieving the desired chocolate quality. This energy helps to break down sugar crystals and cacao particles, reducing the particle size and creating a smoother texture.

But conching isn’t just about texture; it also plays a significant role in developing the chocolate’s aroma through flavour redistribution. As the chocolate is mixed and aerated, volatile compounds are released, allowing the flavours to meld together harmoniously.

Vanquishing Volatile Villains

Volatile compounds are chemicals that easily evaporate at room temperature, contributing to the aroma and flavour of food. In cacao beans, some volatile compounds can impart undesirable flavours, such as astringency or bitterness.

The conching process helps to remove these unwanted volatile compounds, resulting in a smoother, more mellow chocolate flavour.

During conching, the chocolate mixture is exposed to air and heat, which encourages the evaporation of volatile compounds.

As these compounds are released, the overall flavour profile of the chocolate becomes more balanced and refined.

These compounds can include:

- Acetic acid: This sharp, vinegary note is often associated with poorly fermented or dried cacao beans. Conching helps to volatilize and remove this unpleasant acidity.

- Aldehydes: Certain aldehydes, like hexanal and nonanal, can contribute grassy, green, or fatty off-flavours to chocolate. The elevated temperatures and aeration during conching encourage the evaporation of these compounds.

- Ketones: Some ketones, such as 2-heptanone and 2-nonanone, impart musty, cheesy, or rancid notes that are undesirable in fine chocolate. Conching reduces the concentration of these volatile ketones, allowing the true cacao flavour to shine through.

The removal of harsh or unpleasant volatiles allows the desirable flavours, such as nuttiness, fruitiness, or caramel notes, to shine through.

No Need for Speed: Stone Cold Conching Preserves the Soul of Your Chocolate

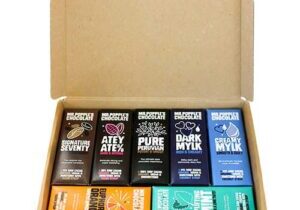

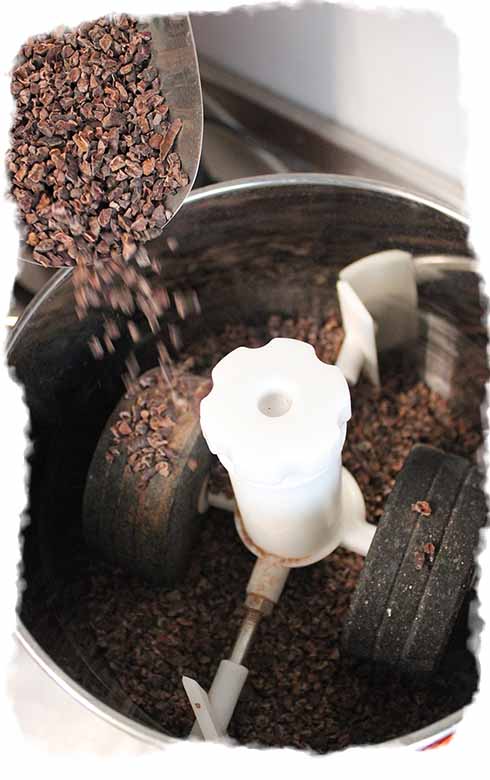

At Mr Popple’s Chocolate, we rely on the traditional method of stone grinding for our conching process. This slow, gentle approach allows us to achieve the perfect texture and flavour profile, whilst keeping intact the delicate nurtitious compounds that easily get destroyed by heat.

For an example of such compounds, please see the results from the independant study that showed our chocolate to have the highest amounts of antioxidants and polyphenols out of all of the chocolate tested.

Key Factors Influencing the Conching Process

Several key factors, such as time, temperature, and ingredients, can significantly impact the final product during the conching process. Longer conching times and higher temperatures generally result in a smoother, more mellow chocolate, while shorter times and lower temperatures can preserve some of the chocolate’s brighter, fruitier notes.

Emulsifiers like lecithin are often added during the conching process to reduce friction and improve the chocolate’s texture.

However, at Mr Popple’s Chocolate, we choose to conche without emulsifiers, relying instead on the natural properties of our carefully selected ingredients.

Conching Without Emulsifiers: A Growing Trend Among Craft Chocolate Makers

In recent years, there has been a growing trend among craft chocolate makers to avoid using emulsifiers like lecithin in their chocolate. Some believe that emulsifiers can mask the unique flavours of the cacao, while others prefer to keep their ingredient lists as simple and natural as possible.

Conching without emulsifiers presents its own set of challenges, as it can be more difficult to achieve the desired smooth texture. However, the rewards are well worth the effort, as the resulting chocolate showcases the pure, unadulterated flavours of the cacao.

At Mr Popple’s Chocolate, we’ve perfected the art of conching without emulsifiers, relying on the natural properties of our organic cacao butter and extended conching times in our stone grinders to achieve the silky smooth texture our chocolate is known for.

Conclusion

The science of chocolate conching is a fascinating blend of art and science, transforming a gritty mixture into the smooth, decadent treat we all know and love. By understanding the key factors that influence the conching process, bean-to-bar chocolate makers can craft chocolate that showcases the unique flavours of their carefully selected cacao.

At Mr Popple’s Chocolate, our years of expertise and dedication to the craft have allowed us to perfect the conching process, resulting in chocolate with a silky smooth texture and unparalleled flavour. We invite you to experience the difference for yourself and savour the delightful results of our conching expertise.