BLOG

The Gloss: Comparing Different Cacao Tempering Techniques for Bean-to-Bar Chocolate

Have you ever wondered why some chocolate bars have that irresistible snap and glossy sheen, while others look dull and crumbly?

The secret lies in a process called tempering, and it’s absolutely crucial in the world of bean-to-bar chocolate making.

Tempering is a bit like alchemy – it’s where science meets magic in the chocolate-making process. It involves carefully manipulating the temperature of melted chocolate to ensure that the cocoa butter crystals form in just the right way. When done properly, tempering gives chocolate its signature snap, glossy appearance, and melt-in-your-mouth texture that we all crave.

Why Tempering Matters: The Science Behind the Magic

At its core, tempering is all about controlling the crystallization of cocoa butter.

Cocoa butter, the natural fat in chocolate, can crystallize in six different forms.

Only one of these forms – the beta crystal – gives chocolate its desirable qualities. Tempering ensures that we encourage the formation of these beta crystals, resulting in chocolate that’s stable at room temperature and has that satisfying ‘snap’ when you break it.

Curious about the nitty-gritty details of cocoa butter crystallization? We’ve got a full article that dives deep into the science of chocolate tempering – it’s a fascinating read for all you chocolate geeks out there!

When chocolate is properly tempered, you’ll notice several benefits:

- A glossy, smooth surface that’s a feast for the eyes

- A satisfying snap when you break it

- A smooth, creamy mouthfeel as it melts on your tongue

- Resistance to bloom (that whitish coating that sometimes appears on chocolate)

- Better shelf stability at room temperature

Traditional Tempering Methods: The Tried and True Techniques

Now, let’s explore some of the classic methods for tempering chocolate. These techniques have stood the test of time and are still widely used by artisanal chocolatiers around the world.

The Seeding Method: Simplicity Meets Precision

The seeding method is often considered the easiest and quickest way to temper chocolate. Here’s how it works:

- Melt about two-thirds of your chocolate to 45°C (113°F) for dark chocolate, or 40-42°C (104-108°F) for milk and white chocolate.

- Remove from heat and add the remaining third of chopped, tempered chocolate or tempered cacao butter (the ‘seed’).

- Stir continuously until all the chocolate melts and cools to about 31-32°C (88-90°F) for dark chocolate, or 29-30°C (84-86°F) for milk and white chocolate.

Pros: – Relatively easy to master – Works well for small batches – Less equipment needed

Cons: – Can be time-consuming for larger quantities – Requires precise temperature control

The Tabling Method: A Test of Skill and Patience

The tabling method is a bit more hands-on and requires some practice to perfect. It uses a marble or granite surface to cool the chocolate while manipulating it. Here’s a quick rundown:

- Melt the chocolate to 45°C (113°F) for dark chocolate, or 40-42°C (104-108°F) for milk and white chocolate.

- Pour about two-thirds of the melted chocolate onto a cool marble or granite surface.

- Using a scraper and palette knife, spread and gather the chocolate repeatedly to cool it down to about 27°C (81°F).

- Return the cooled chocolate to the bowl with the remaining warm chocolate and stir to bring it to working temperature.

Pros: – Gives you great control over the tempering process – Ideal for larger batches – Develops a real feel for the chocolate

Cons: – Requires skill and practice – Can be messy and labour-intensive – Needs specific equipment (marble slab, scrapers)

The Ice Water Bath Method: A Cool Alternative

This method is a bit of a wildcard but can be effective when you’re in a pinch. Here’s how it goes:

- Melt your chocolate as usual.

- Prepare a large bowl of ice water.

- Place your bowl of melted chocolate on top of the ice water bath.

- Stir constantly, monitoring the temperature carefully.

- Once it reaches the right working temperature, remove from the ice bath and use immediately.

Pros: – Can be quick if done correctly – Doesn’t require special equipment – Good for small batches

Cons: – High risk of over-cooling or introducing water to the chocolate – Requires constant attention and temperature monitoring – Not ideal for beginners

Modern Marvels: Cutting-Edge Chocolate Tempering Techniques

Fancy a bit of 21st-century magic in your chocolate-making adventure? Let’s dive into some modern tempering techniques that are shaking up the bean-to-bar world!

Sous Vide Tempering: Precision in a Water Bath

Ever thought about using your sous vide machine for chocolate? It’s not just for perfectly cooked steaks, you know! Here’s how it works:

- Seal your chocolate in a water-tight glass container.

- Set your sous vide to the exact tempering temperature for your chocolate type.

- Submerge the container and let the machine work its magic.

- Once tempered, remove and use as needed.

Pros: – Incredibly precise temperature control – Hands-off process – Consistent results

Cons: – Requires specialised equipment – Can be slow for large batches – Limited tactile involvement in the process

Microwave Tempering: Quick and Convenient

In a rush? Your trusty microwave might be the answer. Here’s a speedy method:

- Chop chocolate finely and microwave in short bursts, stirring between each.

- Once mostly melted, stir vigorously to distribute heat evenly.

- Continue microwaving and stirring until it reaches the correct working temperature.

Pros: – Fast and convenient – Great for small batches – Minimal equipment needed

Cons: – Easy to overheat the chocolate – Requires careful monitoring – Can be inconsistent

Tempering Machines: The Professional’s Choice

For those serious about their chocolate craft, tempering machines are a game-changer. These come in various types:

- Batch tempering machines

- Continuous tempering machines

- Tabletop tempering machines

Advantages: – Consistent results – Large capacity – Precise temperature control

Limitations: – Expensive initial investment – Require maintenance and cleaning – Can be overkill for small-scale producers

Bean-to-Bar Brilliance: Tempering Considerations

When you’re crafting bean-to-bar chocolate, tempering isn’t just a final step – it’s an art form that starts with the beans themselves.

The Cacao Content Conundrum

Did you know that the cacao content of your chocolate significantly impacts the tempering process? It’s true! Higher cacao percentages typically require higher tempering temperatures. For instance, a 70% dark chocolate might need to be heated to 32°C (90°F), while a 55% dark chocolate could be tempered at a slightly lower temperature.

Dark, Milk, or White: Adjusting Your Technique

Each type of chocolate has its own temperamental personality:

- Dark chocolate: The diva of the bunch, requires the highest temperatures and can be the trickiest to temper.

- Milk chocolate: A bit more forgiving, but watch out for those milk solids!

- White chocolate: The most delicate of all, prone to scorching if you’re not careful.

Small Batch, Big Challenges

As a small-batch producer, you might face some unique hurdles:

- Temperature fluctuations in smaller quantities of chocolate

- Limited equipment options

- Consistency across batches

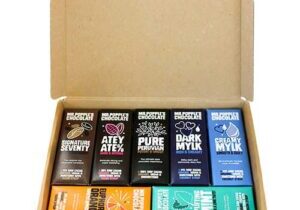

At Mr Popple’s Chocolate, we’ve tackled these challenges head-on, developing techniques that ensure each small batch is as perfectly tempered as the last.

When Things Go Wrong: Troubleshooting Tempering Troubles

Even the most experienced chocolatiers face tempering tribulations from time to time. Let’s look at some common issues and how to solve them:

Bloom: The Chocolatier’s Nemesis

Ever noticed a whitish coating on your chocolate? That’s bloom, and it’s usually caused by improper tempering or storage. To fix it:

- Re-temper the chocolate completely

- Ensure proper storage conditions (cool, dry place)

- Check for temperature fluctuations during the tempering process

Overheating and Seizing: A Sticky Situation

Overheated chocolate can seize, turning into a grainy, unworkable mess. If this happens:

- Add a small amount of cocoa butter or vegetable oil

- Stir gently until smooth

- Re-temper from scratch if necessary

Inconsistent Results: The Tempering Rollercoaster

If your results are hit-or-miss, consider:

- Investing in a good thermometer

- Keeping detailed notes of your process

- Practicing, practicing, practicing!

Remember, even the pros have off days. The key is to learn from each batch and keep refining your technique.

Choosing Your Tempering Technique: A Bean-to-Bar Maker’s Guide

So, how do you decide which tempering method is right for you? Consider these factors:

- Batch size: Are you making a few bars, a few hundred, or a few thousand?

- Equipment: What tools do you have at your disposal?

- Time: How much can you dedicate to the tempering process?

- Consistency: How important is uniformity across batches?

For small-scale producers, manual methods like seeding or tabling can be ideal. As you scale up, investing in a tempering machine might be worth considering.

Wrapping Up: The Sweet Science of Tempering

Tempering is where science meets art in the world of chocolate making. It’s a skill that takes time to master, but the results are oh-so-worth it. Whether you’re using traditional methods or embracing modern technology, the key is to understand the principles behind tempering and to practice, practice, practice.

At Mr Popple’s Chocolate, we’ve spent years honing our tempering techniques to create bars that not only taste divine but look and feel perfect too. We encourage you to experiment with different methods and find what works best for you. After all, that’s the beauty of bean-to-bar chocolate making – it’s a journey of constant discovery and delicious results.

So, are you ready to embark on your tempering adventure? Remember, every great chocolatier started somewhere. With patience, persistence, and a passion for chocolate, you’ll be creating perfectly tempered treats in no time. Happy tempering!